Each test result was recorded and a mathematical model was created.

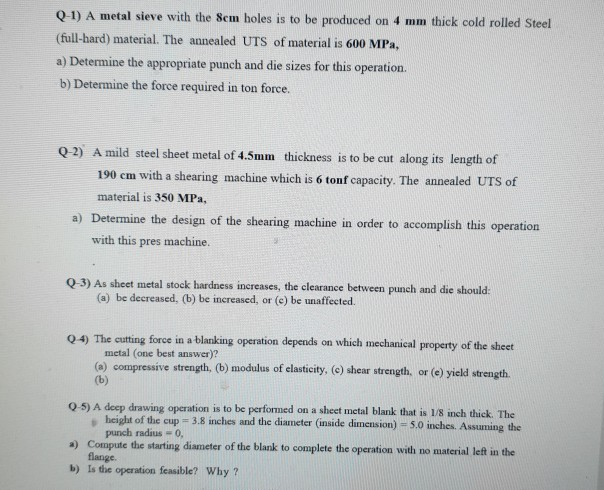

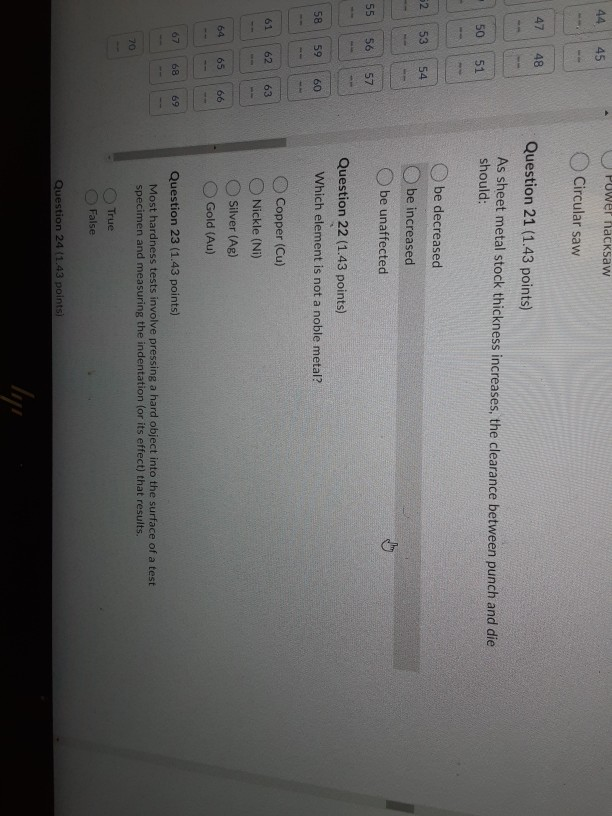

As sheet metal stock thickness increases the clearance between punch and die should.

The greater the sheet metal thickness the higher the clearance value should be.

Here s how to estimate die clearance required for punching steel and aluminium.

A large factor is the type of work material and its temper.

Enter information about the stock you are punching in rows a b and c below.

For more information please read proper die clearance.

The sheet is placed between the two and held in place by the backstop.

Material thickness x 15 example.

A circular sheet metal slug produced in a hole punching operation will have the same diameter as the.

This depth is precisely controlled to achieve the required bend.

20 25 long service life of dies.

250 x 15 0375.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be.

Determine the punch and die clearance by experience.

A be decreased b be increased or c be unaffected.

Increased 16 7 a circular sheet metal slug produced in a hole punching operation will have the same diameter as the a die opening or b punch.

16 6 as sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

B a circular sheet metal slug produced in a hole punching operation will have the same diameter as a the die opening or b the punch.

In manufacturing industry there is a range of optimum values for specific processes clearances may span from 1 to 30 of sheet thickness.

As sheet metal stock hardness increases the clearance between punch and die should.

Use it to calculate die clearance required for perforating metals plastics and more.

A circular sheet metal slug produced in a hole punching operation will have the same diameter as a the die opening or b the punch.

30 heavy duty die clearance.

The press brake contains an upper tool called the punch and lower tool called the die between which the sheet metal is placed.

Generally typical values span from 3 to 8 of sheet thickness.

30 table 1 recommended die clearance table.

B be increased a round sheet metal slug produced in a hole punching operation will have the same diameter as.

The bend angle is determined by the depth that the punch forces the sheet into the die.

Min service life of dies.

How to estimate die clearance required for punching.

Let s make holes faster.